ISOFLUX™

|

|

|

Descripción : |

Tubular ceramic membranes entirely made for food processing & bio-industries. The ISOFLUX™ membrane improves performances of existing separations and allows separations which were difficult or impossible to make before.

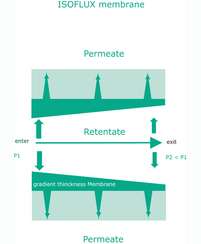

The ISOFLUX™ membrane allows obtaining a constant permeate flux on each point of the membrane without using a complex and expensive system. To obtain this result the thickness of the separating layer decreases from the inlet to the outlet in order that the ratio pressure/thickness of the layers stays constant.

In opposition to classical membranes for which the permeate flux decreases from the inlet to the outlet, the ISOFLUX™ membrane allows obtaining a permeate flux independent on the position where it is measured.

|

|

Aplicación : |

Food processing:

- Milk bacteria removal

- Whey bacteria removal

- Milk casein / whey protein separation

- Fat / protein separation from whey

- Syrup bacteria removal

Bio-industry:

- Enzyme / protein extraction from the fermentation broth

- Bacteria / active principal separation

|

|

Beneficios : |

- High performances

- Simple use (classic filtration loop)

- Flexible use (important latitude in terms of work, pressure, standard cleaning)

- Reduced risk of fouling because

- All the channels work in identicaly way

- The membrane layer remains fine despite its tichkness gradient

- The support of membrane is standard

- Geometrical configuration compatible with other existing industrial units.

|

Diámetro externo :

Ø 25 L=1178mm* |

Number of channels : |

Hydraulic diameter : |

Area (sqm) : |

Available cut-offs** : |

|

08 |

6 |

0,20 |

MFT |

|

23 |

3,5 |

0,35 |

MFT |

|

49 |

2,5 |

0,5 |

MFT |

*Available lengths: 1020, 1178 mm.

** MFT 0,14µm, 0,20 µm, 0,45 µm, 0,80 µm, 1,2 µm, 1,4 µm.